GB/T 2951—2008 电缆绝缘和护套材料通用试验方法

GB/T 2952 电缆外护层

GB/T 3048—2007 电线电缆电性能试验方法

GB/T 3956 电缆的导体

GB 5441—85 通信电缆试验方法

GB/T 6995 电线电缆识别标志

GB/T 9330.1-2008 塑料绝缘控制电缆 第1部分: 一般规定

GB/T 17650-1998 取自电缆或光缆的材料燃烧时释出气体的试验方法

GB/T 19666-2005 阻燃和耐火电线电缆通则

JB/T 8137—1999 电线电缆交货盘

JB/T 10696.7-2007 电线电缆机械和理化性能试验方法 第7部分:抗撕试验

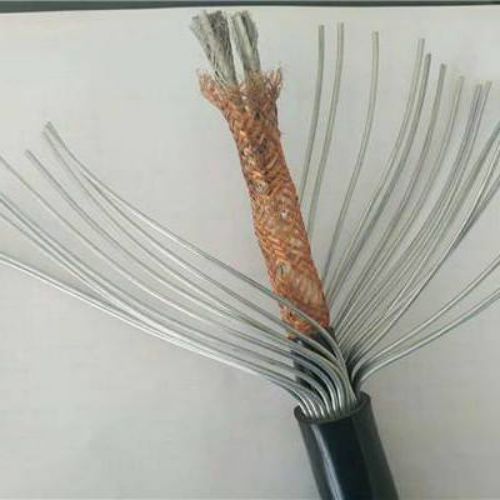

ZR-IA-DJYVP3*2*1.5计算机电缆生产流程:

1、导体

2、导体采用软铜单线绞合而成(多股),其性能符合GB/T3956的规定。

3、导体表面光洁、无油污、无损伤绝缘的毛刺、锐边、无凸起或断裂的单线。

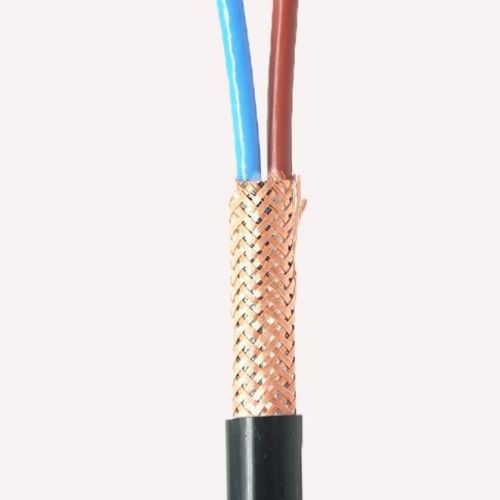

4、绝缘材料为氟塑料,采用镍基合金高温挤出机高速生产,挤包在导体上的绝缘性能符合Q/321023KLA11的规定。

5绝缘标称厚度符合Q/321023KLA11的规定,绝缘厚度平均值不小于规定的标称值,绝缘任一点Z薄点的测量厚度不小于标称值的90%减去0.1mm。

6、火花

生产过程中绝缘层中间检验应按GB/T3048规定进行交流50HZ 6KV火花耐压试验。

7、对绞

对绞组采用颜色识别标志,每对线组由两根不同颜色的单线和一条双色扎带组成。

8、对绞节距应不大于100mm。相邻对绞组节距应不相同。

9、对绞屏蔽(二线组或三线组)

ZR-IA-DJYVP3*2*1.5计算机电缆规格参数:

导体标称 截面mm2 | 导体根数/单丝直径mm | 20℃时导体直流电阻Ω/km | |||

A | B | R | A/B | R | |

1*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

1*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

1*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

1*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

1*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

2*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

2*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

2*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

2*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

2*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

3*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

3*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

3*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

3*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

3*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

4*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

4*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

4*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

4*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

4*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

5*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

5*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

5*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

5*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

5*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

6*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

6*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

6*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

6*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

6*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

7*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

7*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

7*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

7*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

7*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

8*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

8*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

8*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

8*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

8*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

10*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

10*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

10*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

10*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

10*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

12*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

12*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

12*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

12*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

12*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

14*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

14*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

14*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

14*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

14*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

15*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

15*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

15*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

15*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

15*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

16*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

16*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

16*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

16*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

16*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

18*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

18*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

18*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

18*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

18*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

20*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

20*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

20*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

20*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

20*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

22*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

22*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

22*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

22*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

22*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

24*2*0.5 | 1/0.80 | 7/0.30 | 16/0.20 | ≤36.0 | ≤39.0 |

24*2*0.75 | 1/0.97 | 7/0.37 | 24/0.20 | ≤24.5 | ≤26.0 |

24*2*1.0 | 1/1.13 | 7/0.43 | 32/0.20 | ≤18.1 | ≤19.5 |

24*2*1.5 | 1/1.38 | 7/0.52 | 30/0.25 | ≤12.1 | ≤13.3 |

24*2*2.5 | 1/1.78 | 7/0.68 | 49/0.25 | ≤7.41 | ≤7.98 |

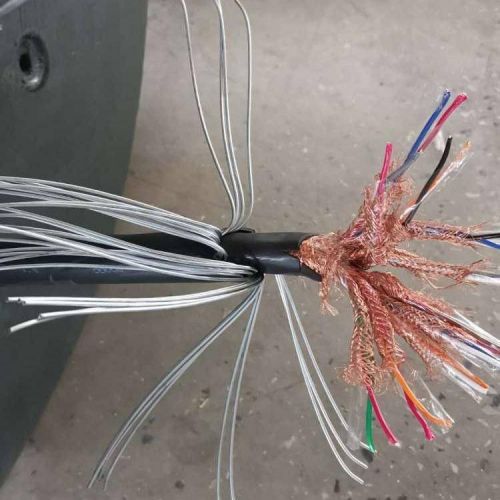

IA-DJYPVP32-2x2x1.5钢丝铠装计算机电缆

IA-DJYPVP32-2x2x1.5钢丝铠装计算机电缆  DJFPV 1x2x1.5计算机屏蔽电缆

DJFPV 1x2x1.5计算机屏蔽电缆  ZR-DJYPVP32钢丝铠装计算机电缆

ZR-DJYPVP32钢丝铠装计算机电缆  ZR-DJVVP-2x2x1.5阻燃计算机电缆

ZR-DJVVP-2x2x1.5阻燃计算机电缆